-

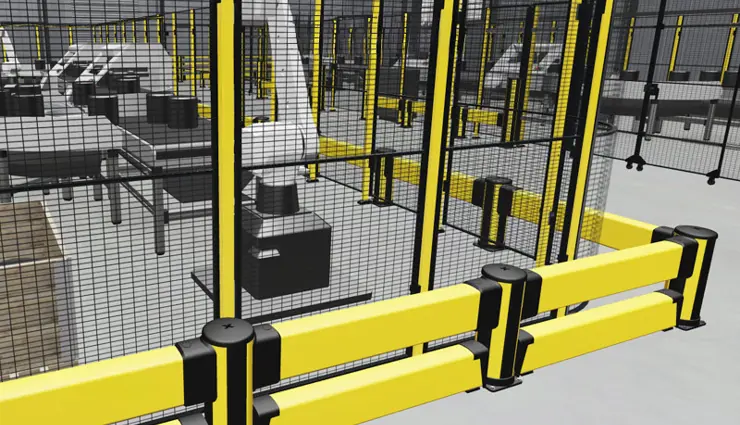

Machine Guarding

Machine guarding

Axelent is one of the market's leading manufacturers of machine guards. The complete system that we deliver meets current directives and standards.

-

Warehouse

Axelent is one of the market’s leading brands of mesh panels for industry and warehouse environments

Axelent is one of the market’s leading brands of mesh panels for industry and warehouse environments. Our products and systems ensure flexible and quick-fitting solutions at all stages from drawing preparation to final product assembly.

Separating walls and cage solutions

Prevention of falling goods - pallet racks

Fall protection System

Mesh shelving

-

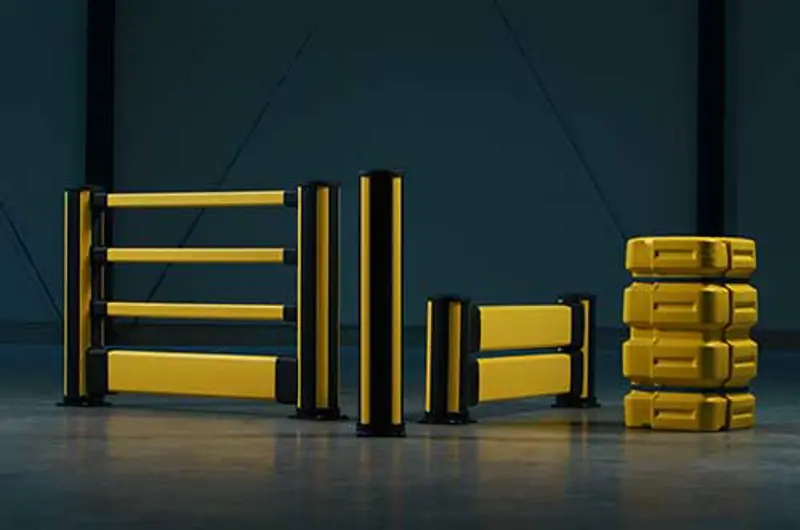

Impact

Impact protection

X-Protect is Axelent's range of impact protection. We offer all impact protection you need, from bollards to safety barriers, column guards and pedestrian barriers.

-

Cable Basket Tray

X-Tray Cable Trays - Cable Management Solutions

X-Tray is Axelent's own cable management system. It has the market's widest range, both in terms of material and function. We have a wide range of cable tray sizes available in our Australian warehouse.