Subchapter 4.1

Mobile autonomous machinery

This section explores the safety aspects of industrial mobile robots (IMRs) such as AGVs and AMRs. You will learn how these systems operate, where risks arise, and what protective measures, both built-in and additional, are recommended to ensure safe interaction between people and mobile automation systems.

Flexible transport with AGVs and AMRs

Industrial mobile robots (IMR), such as automatic guided vehicles (AGV) and autonomous mobile robots (AMR) can transport diverse storage units to/from storage locations.

They may lift, carry and move pallets, entire racks or even very large unit loads but are more likely to be used for boxes, bins and totes. They are mainly employed in “goods to person” strategies for case and each picking but may also serve intermediate transport tasks in a “person to goods” scheme.

Typical load handling methods of IMRs

There are five main ways IMRs pick and place loads (combinations of these may also be used):

- AGVs serving as unmanned forklift trucks that move pallets.

- A robot, linear handling, or conveyor system places the load on top of the vehicle (such vehicles are often referred to as “undercarts”; they may have very low heights of only 50 to 300 mm).

- The IMR has a conveyor on top for takeover; some IMRs may telescope the conveyor into a shelf to retrieve it, grippers may be provided to assist picking/securing.

- The IMR moves underneath a load, lifts it up and moves it; entire racks may thus be lifted and transferred to an order picking workplace and back to the warehouse (such systems are often referred to as ASRS = Automated Storage and Retrieval Systems).

- A robot on top of an IMR picks items, puts them in a box or on a platform, transports, and then places them in a target location; such IMRs may also serve production functions, such as cleaning, polishing, inspection etc.

Common hazards in IMR environments

While IMRs are equipped with advanced safety features, certain risks remain, especially when people become inattentive or accustomed to their presence.

In emergencies, mobile robots may also obstruct escape routes. The following list outlines key hazards that should be carefully considered when planning and implementing IMR systems:

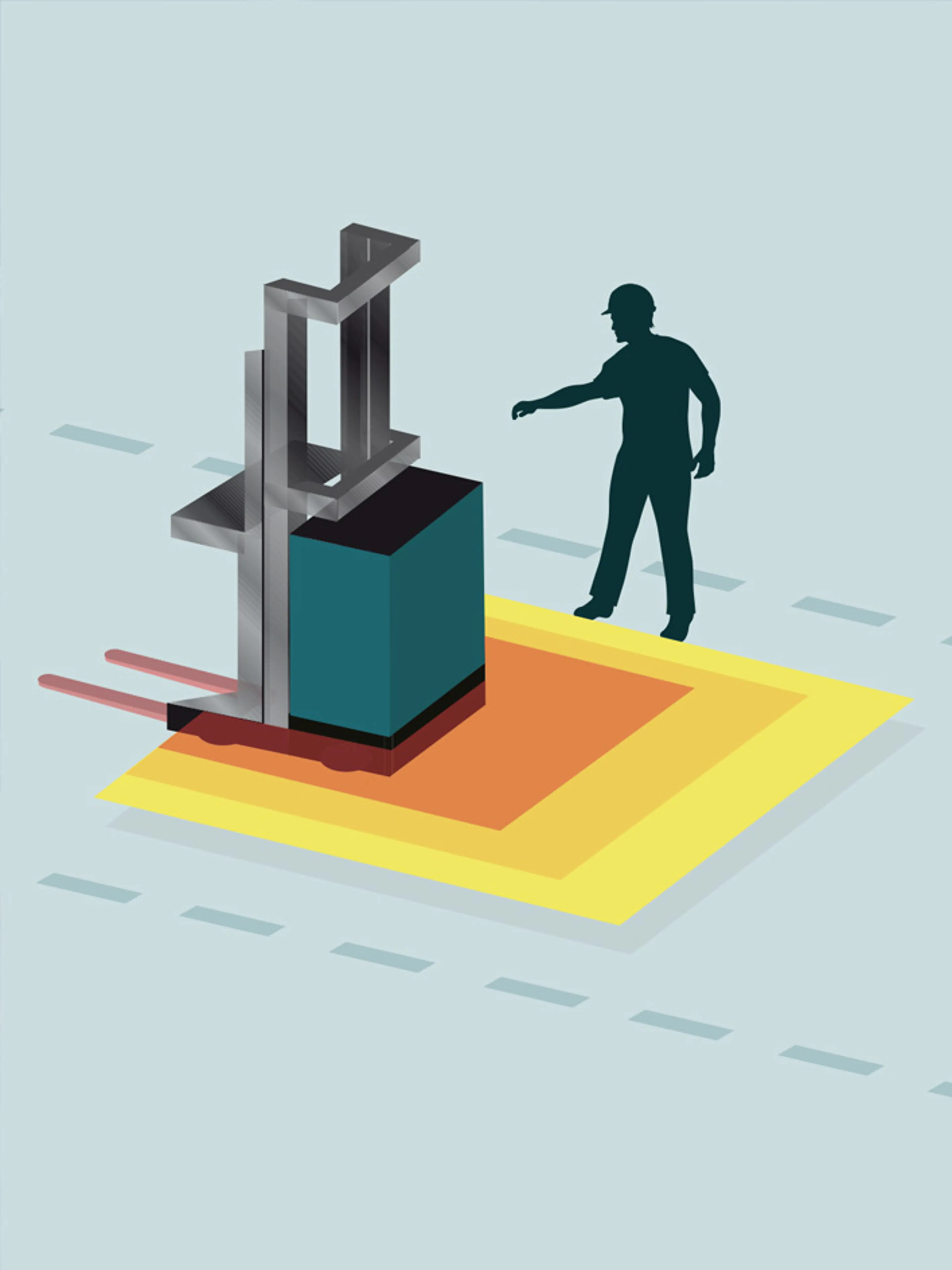

- Collision risk - impact or running over of people, especially where IMRs and pedestrians share space or when vehicles access manual workstations.

- Underride hazard - low-height IMRs may pass under equipment or fencing if floor gaps are too large.

- Crushing/shearing with surroundings - in tight areas like racking, narrow aisles, doorways, machinery, or structural parts.

- Load handling risks - crushing and shearing during docking, charging, or load transfer.

- Toppling loads - risk of impact from unstable or falling items.

- Localisation errors - accidents due to failure or mis-localisation, especially near stairs, ramps, loading docks, blind corners, etc.

- Deactivated sensors - presence-sensing may be suspended during docking or transfer.

- Undetected people - presence of people in blind spots outside sensor range.

- Add-on equipment risks - hazards from tools like conveyors, grippers, or robotic arms mounted on IMRs.

IMR safety features and standards

All IMRs feature presence-sensors that will prevent accidents.

The vehicles generally move slowly in areas roamed by people and stop when they encounter obstacles or people in their path. Most IMRs can be programmed to avoid virtual restricted and keep-out zones and some additionally feature bumpers for switch-off upon impact.

Passive safety features included are emergency stop buttons, warning lights and alarm signals. The safety requirements for AGVs and IMRs are laid down in (EN) ISO 3691-4 as well as ANSI/RIA R15.08-1 and ANSI/ITSDF 56-5 for the USA. You can find more information about the standards in chapter 5.3 Industrial safety standards.

Based on this and supported by thorough risk assessments, the following measures may be necessary to ensure a safe working environment.